Another method to check the impact strength indirectly is the breaking-point test. Cutting the steel and hitting it with a hammer break the sample (e.g. knife) as in Izod's test. https://en.wikipedia.org/wiki/Izod_impact_strength_test When viewing a broken specimen under a magnifying glass, we compare it with the standard Jernkontoret or ASTM steel breakthrough scale.

Fig. 1 Breaking-point scale of Jercontoret [1]

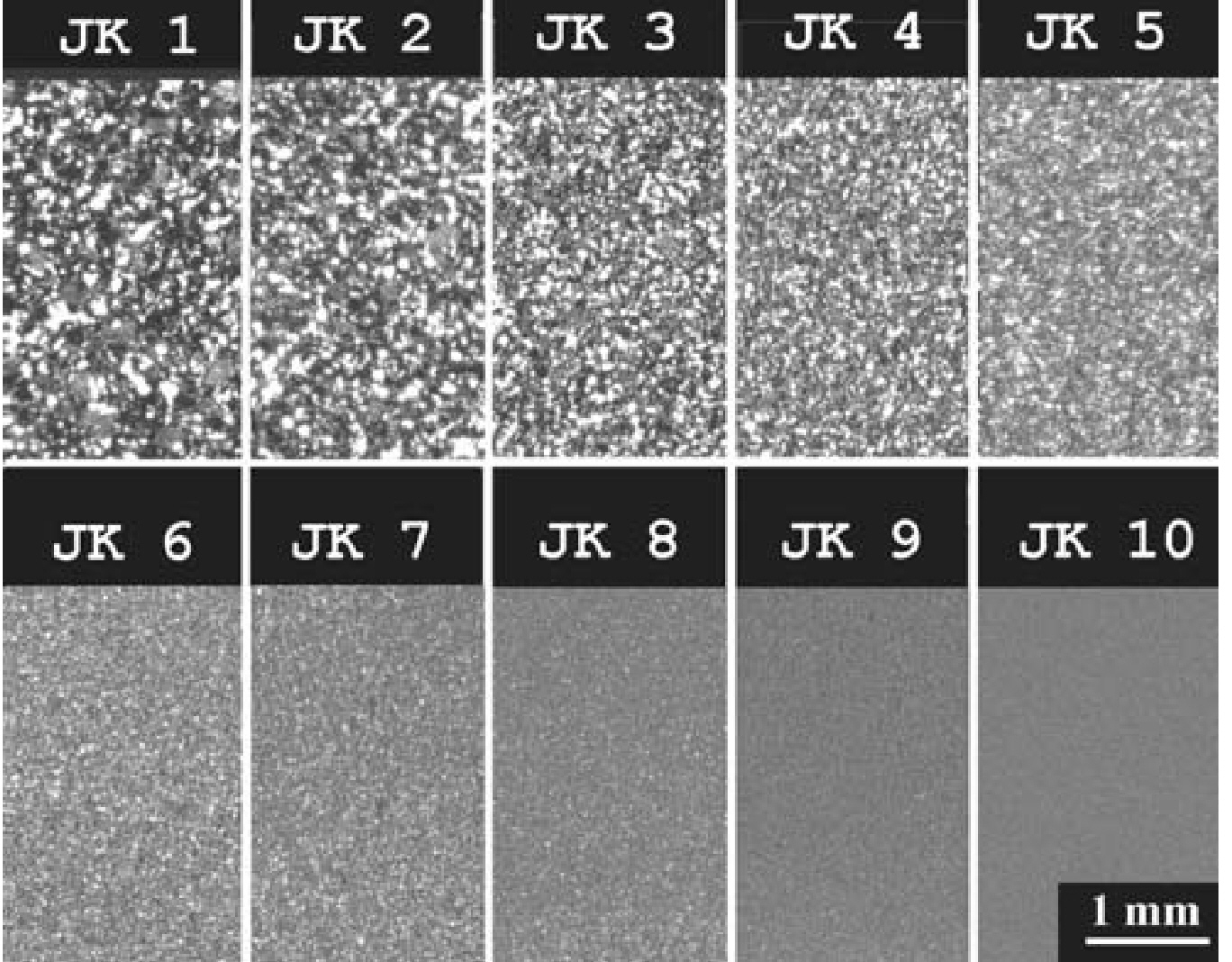

Fig. 2 Breaking-point scale of Jercontoret [2]

Fig. 3 Broken knife, correct fracture, correct ductility [1].

Fig. 4 Broken knife, bad fracture, low ductility [1]

Samples from 1 to 5 posses insufficient resistance to cracking (ductility), samples 6-8 have correct impact strength, samples 9-10 are what we expect from a knife with a high resistance to cracking (and the right hardness, of course)! After hardening a given batch of knives, the knife manufacturer may break one of the knives in the batch, or make a sample especially for breaking (cheaper). It's easy, cheap and reliable.

Bending the blade and breaking the samples are destructive methods that are only used by manufacturers. But how do you check at home if the knife has enough resistance to cracking? The method is indirect, but easy and effective. You need to sharpen the knife on the so-called "razor blade", until you shave your hair freely, the hair has to "jump back" during shaving, and the shave has to be "smooth". If you manage to sharpen the knife in this way, the steel in this knife has at least the correct resistance to cracking (ductility).

Another non-destructive indirect test to assess toughness is the bending of the Cutting Edge on a round instrument (plastic lighter, pen, bar Ø>1/4 inch, brass or steel - drill). A sharpened knife, in strong light, is applied with the Cutting Edge to the instrument and gently bent Cutting Edge until it is visible against the light (sun / strong bulb). If Cutting Edge bends permanently: the knife is too low hardened. If the Cutting Edge crumbles: the resistance to cracking is too low. If the cutting edge bends and returns nicely to the previous condition: the knife has the correct hardness and impact strength! Unfortunately not every knife can be checked this way, the knives with low grinding, so called Scandi are difficult to check with this method.

Fig. 5 Mora Knives knife, Scandi cut[3].

Should an EDC knife require as high impact resistance as a chopping knife? Yes, because it will let us sharpen the knife so that it can cut easily and smoothly. And in the event of a fall, an inadvertent hit, we don't have to buy a new one...

Bibliography

[1] http://lipinskimetalart.blogspot.com/2013/07/ziarno-grain.html zdjęcie skali Jernkontoret pochodzi z książki Edward Żmihorski: Stale narzędziowe i obróbka cieplna narzędzi. Warszawa 1970

[2] Komenda Jacek, Marioli Barbara, Hoglund Lars: Recognition of patterns on fracture surfaces by automatic image analysis. Image Anal Stereol 2002.

[3] http://soldiersystems.net/tag/morakniv/

Powered by MELONTOOLS