The mythical toughness of steel for knives, everyone has heard about it, nobody has ever seen it.

Impact strength is the material's resistance to cracking under sudden, rapid load / impact. This is the effort required to break a standardized sample, on a standard machine, under standardized conditions. https://en.wikipedia.org/wiki/Toughness

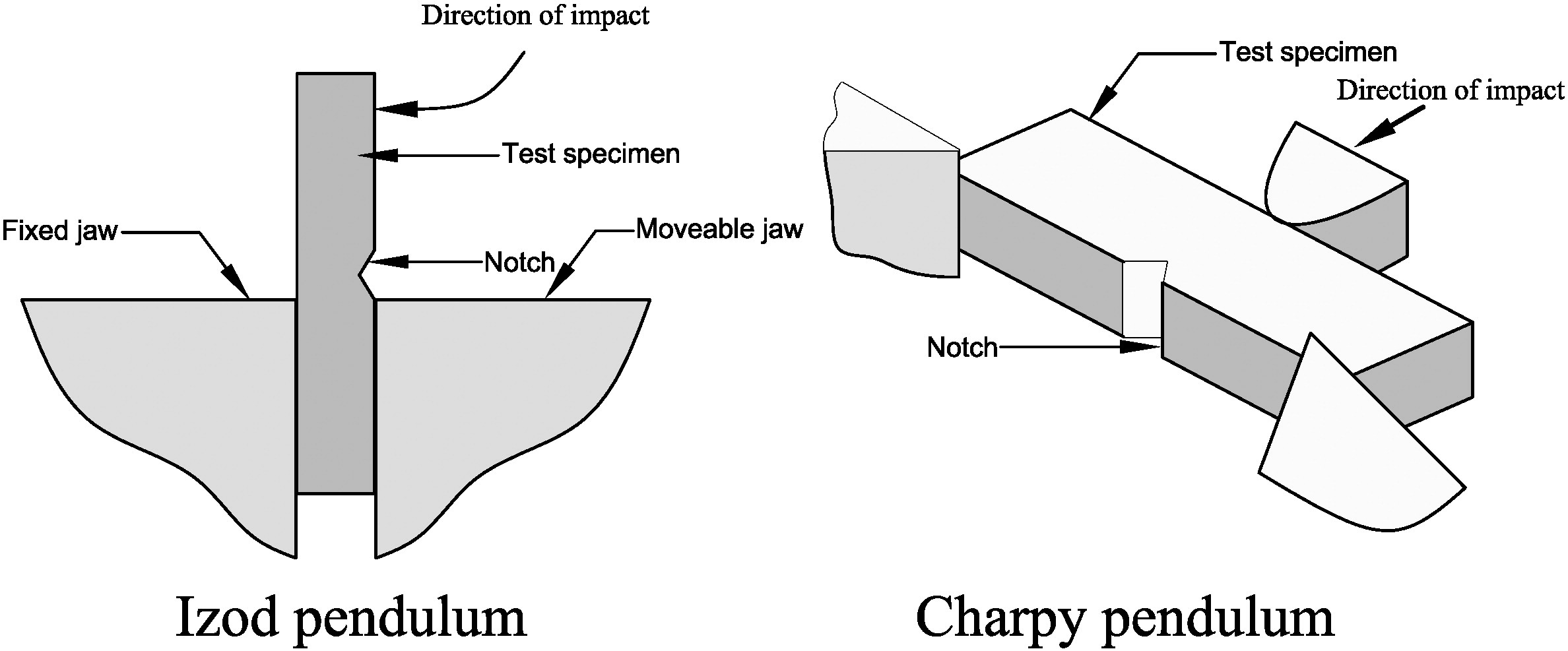

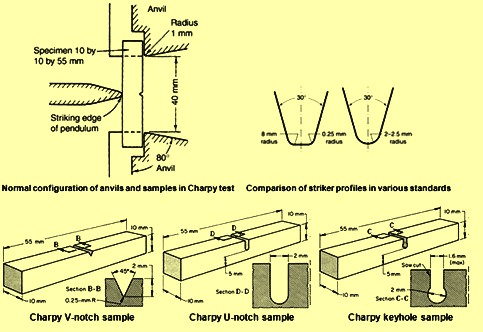

Toughness is most often measured on the Charpy hammer, the result the test is work of breaking , the unit is Joule. https://en.wikipedia.org/wiki/Charpy_impact_test But, but, it's not so simple after all! There are different samples used in this method, and the results obtained on the U-notch sample can not be compared with the V samples! And with adding different Charpy knife radiuses, the combination of unparalleled results can be huge, and we still have Izod's samples!

Fig. 1 The rule of sample breaking in the Charpy and Izod method [1]

Fig. 2 Normal-configuration-of-the Charpy-impact-test [2]

Changing the thickness of the sample, increasing the testing temperature, applying the sample without a notch, Izod method breaking: these are ways to increase the impact strength of the same steel! Manufacturers of tool steels do not make it easier by providing impact strengths in their catalogs without specifying which method has been applied. To make it even worse, the standard hardness test sample has a thickness of 10mm, and the knives? Have much less ... The cooling conditions for hardening knives often have nothing in common with the hardening process of larger cross-sections. Obtained structures, hardness and impact strengths may vary considerably!

Even more variations, how to compare them all? Everyone has heard about high-impact steel for knives! Even about high-impact knives!

Most often the customers can be persuaded by the aggressive marketing of the steel or knives manufacturers. However, there are methods that allow an approximate assessment resistance to cracking (ductility). The industry uses three-point flexural test: https://en.wikipedia.org/wiki/Three-point_flexural_test And how does it translate into knives? If a hardened knife of the same thickness bends in a vise more than the other without deformation and cracking: it has more impact strength! But it is important to point out in this case that thinner knives bend more, it does not translate into greater impact strength.

Fig. 3 bending the knife [3]

So, how to check the impact strength? With hobbyist knife maker’s help or alone at home?

Bibliography

[1] https://www.sciencedirect.com/science/article/pii/S2352012416300236?via%3Dihub

[2] http://ispatguru.com/impact-toughness-testing-of-metals/

[3] https://thenorthedge.wordpress.com/tag/american-bladesmith-society/