"But why do I need all of this information, how is it related to using knives?” The higher the hardness, the higher the resistance to the Cutting Edge (CT) deformation. Because it may seem that we use a low force on the material we are cutting, but that's not the case. The Cutting Edge is similar in cross-section to trapezoidal, its thickness is max. 2μm (in a blunt knife).

Fig. 1 Wood industrial knife [1]

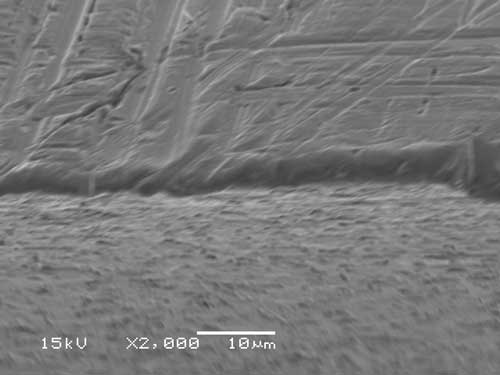

Fig. 2 Blunt industrial wood knife [1]

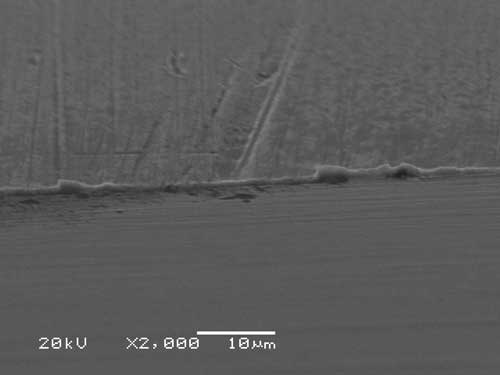

Fig. 3 A sharp industrial wood knife [1]

If you apply a force of 10N (put about 1kg of sugar on the knife) to 10 cm of the blade, it turns out that you act on the cut material at a pressure of more than 0. 5 MPa (5 Atmospheres, 725 Psi). At such high pressures, the cutting edge can deform plastically, the more resistant it will be to such deformations: the longer the knife will remain sharp! And there is no problem with tomatoes and all kinds of meat, but when it comes to cutting, peeling and chopping wood, for example, it starts to be very important. No, when you think about it, cutting tomatoes can also be opressive for the sharpness of the knife: after all, we cut it on a wooden chopping board! The more sharp the knife is, the thinner the cutting edge, the smaller the surface of the Cutting Edge on the board, the more pressure it exerts on steel.

Suitable hardness. The required hardness in the cutting blades increased with technical progress in metallurgy and material engineering. The pre-war knives had a hardness much lower than 50 HRC and people were satisfied. The knives with the higher hardness were fragile. Currently, the acceptable hardness for EDC knives is 55-62 HRC, for bushcraft knives, used mostly in forests, often for chopping the acceptable hardness is min. 50 to 58HRC. This is due to fear of breaking the blades away from civilization. The hardness of the very good and expensive knives produced in Japan is over 65HRC and they do not shatter. This requires very clean and very good steel, very good forging, very good hardeners. Good kitchen knives “keep the sharpness” for a very, very long time.

Aaaaa, and the knife can be sharpened to less than 1μm. It's like a razor blade. . . And then, how it cuts! And the pressure? It grows and grows and grows. . .

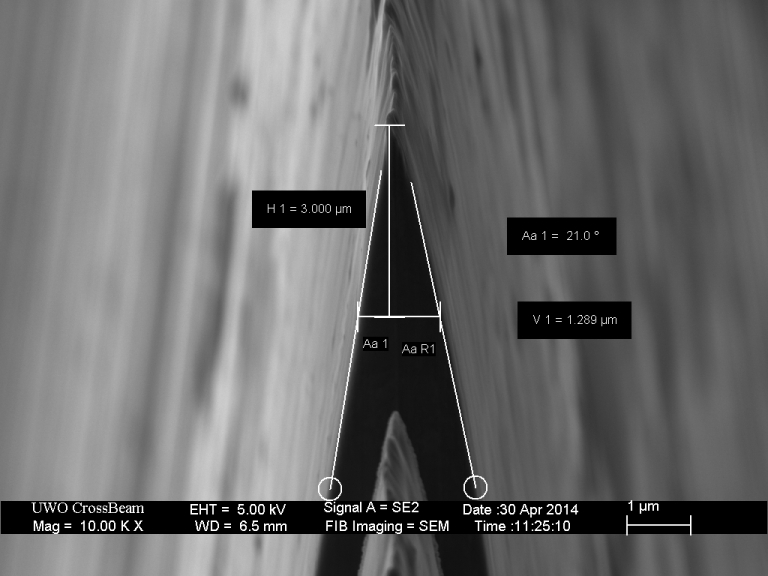

Fig. 4 Old razor blade NOS Gilette blue (third quarter 1959) [2]

(Vintage NOS Gillette blue blade (E3, manufactured third quarter of 1959))

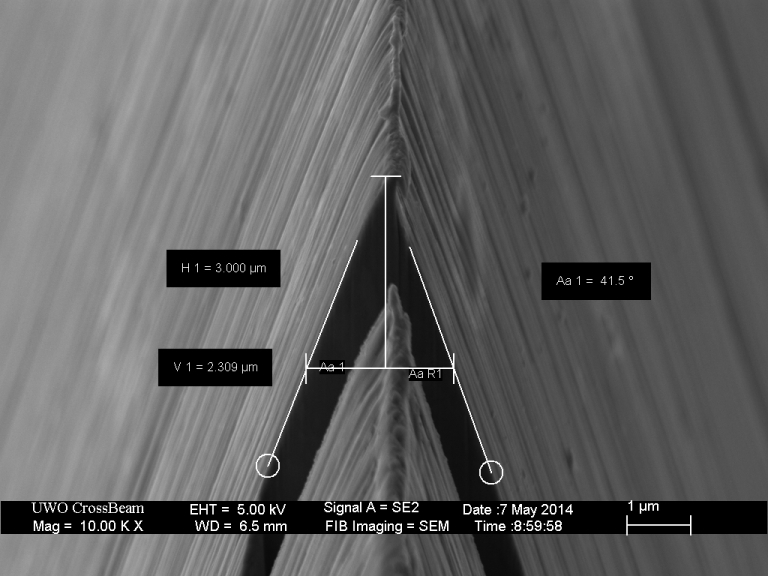

Fig. 5 OLFA disposable blade [2].

(OLFA disposable snap-blade knife)

Bibliography

[1] https://www.popularwoodworking.com/woodworking-blogs/chris-schwarz-blog/sharp-and-dull-for-an-electron-microscope

[2] https://scienceofsharp.wordpress.com/2014/05/28/a-comparison-of-several-manufactured-blades/