To what temperature I heat to, how long to keep the knife at this temperature: the manufacturer often presents it at a temperature scale but usually without the time of Austenitization! In what do I cool it in, how fast do I do it, are even harder questions. The manufacturer often provides special CCT (Continuous Cooling Transformation) diagrams, which are different for different steels, and additionally they change with the annealing temperature for the same steel! https://en.wikipedia.org/wiki/Continuous_cooling_transformation With the help of these graphs people with specialist training are able to calculate the required cooling rate, as well as quite accurately determine the properties of the steel after such cooling. Knowing the cooling speed you can choose the required cooling medium (it is determined by the thickness of detail for example), its temperature, etc.

This is where the first difficulty comes in: most knife manufacturers do not have the expertise and experience to do it!

Everyone wants a hard knife, well hardened, with a high impact resistance, to keep it sharp for a long time, just perfectly tempered.

There are two solutions. Knifemaker has the appropriate, specialized knowledge or hires a heat treatment engineer. Determining the properties of steel after heat treatment, using appropriate diagrams and training, the optimal heat treatment is developed. The second solution is for the knifemaker to learn by his mistakes, often for months and years, on the basis of trial and error. With experience he gets a recipe for good steel.

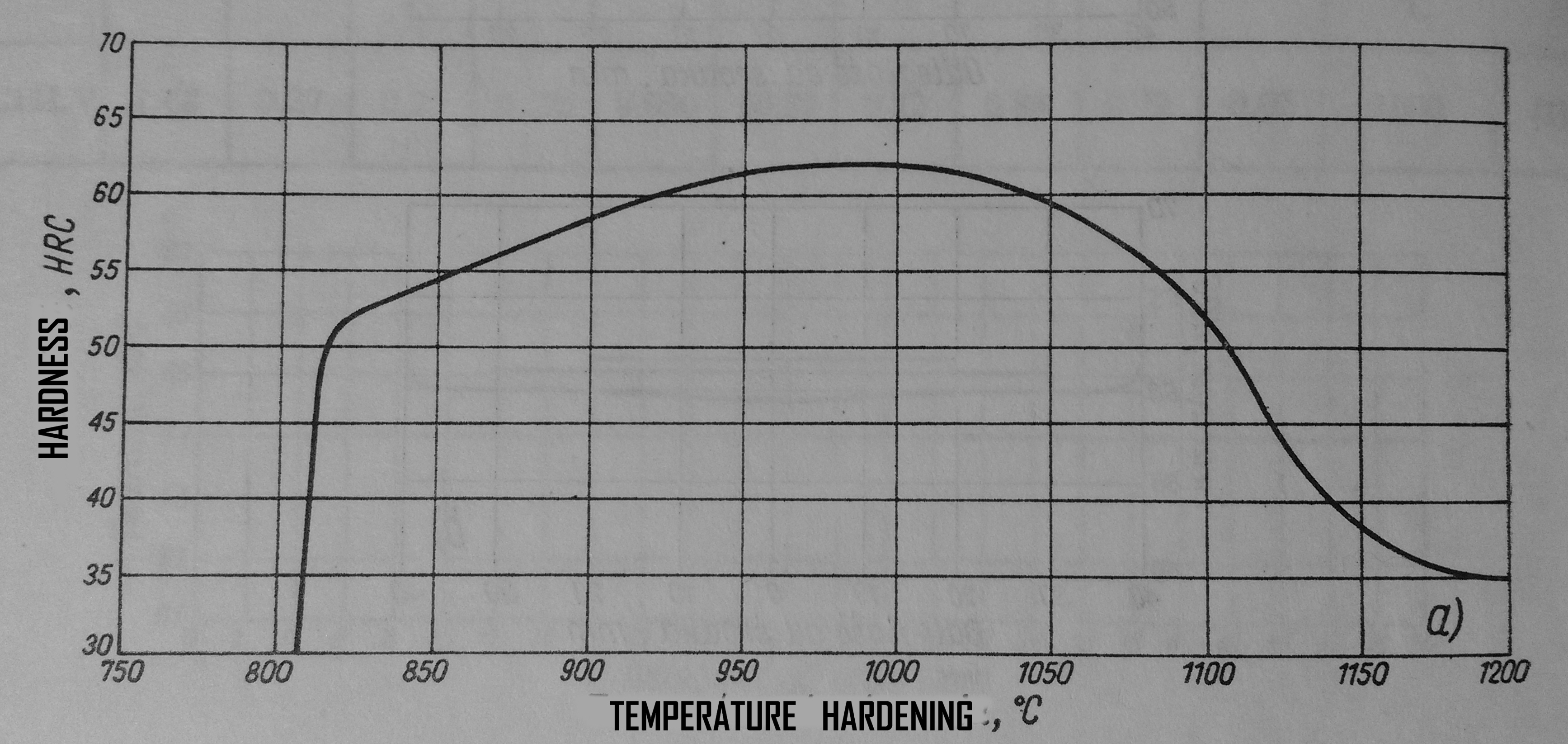

At what temperature should the substance be Austenitized? It is best to select this value from the chart depending on the required hardness!

Fig. 1 Temperature hardening of NC11LV (D2 AISI) steel

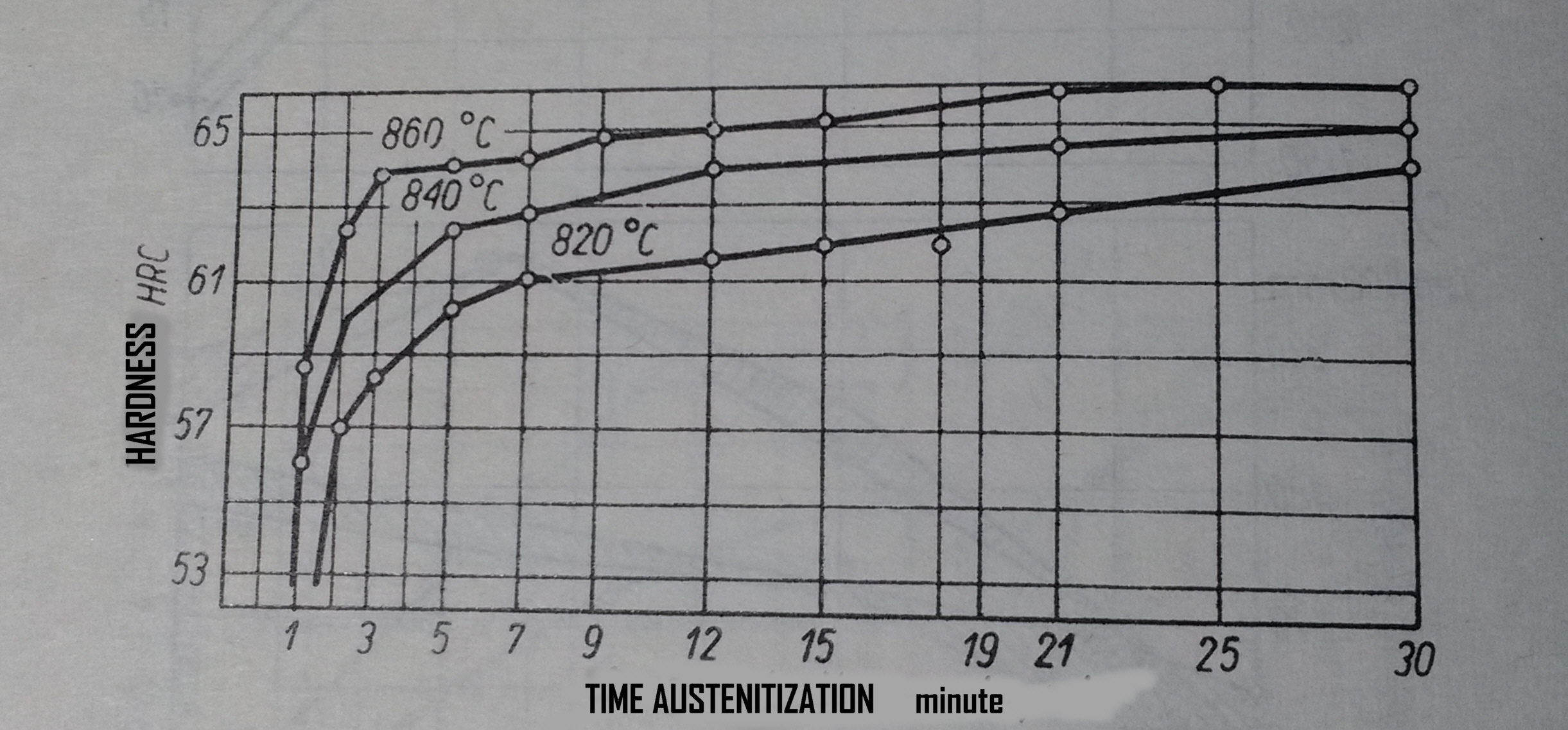

How long should I heat the steel at hardening temperature? It is best to choose from the chart with the hardening temperature!

Fig. 2 Time and temperature of hardening of LH15 steel (52100 AISI)

I won’t say anything about discovering hardening times and temperatures, I've never done it and I never will... Why discover something that has already been researched? If specialist knowledge is not available, the general recommendations of the manufacturer, the standard norm describing steel, can be used to optimize the process by a number of tests. I don't recommend it, it costs a lot of time and money, and the result is usually not ideal...