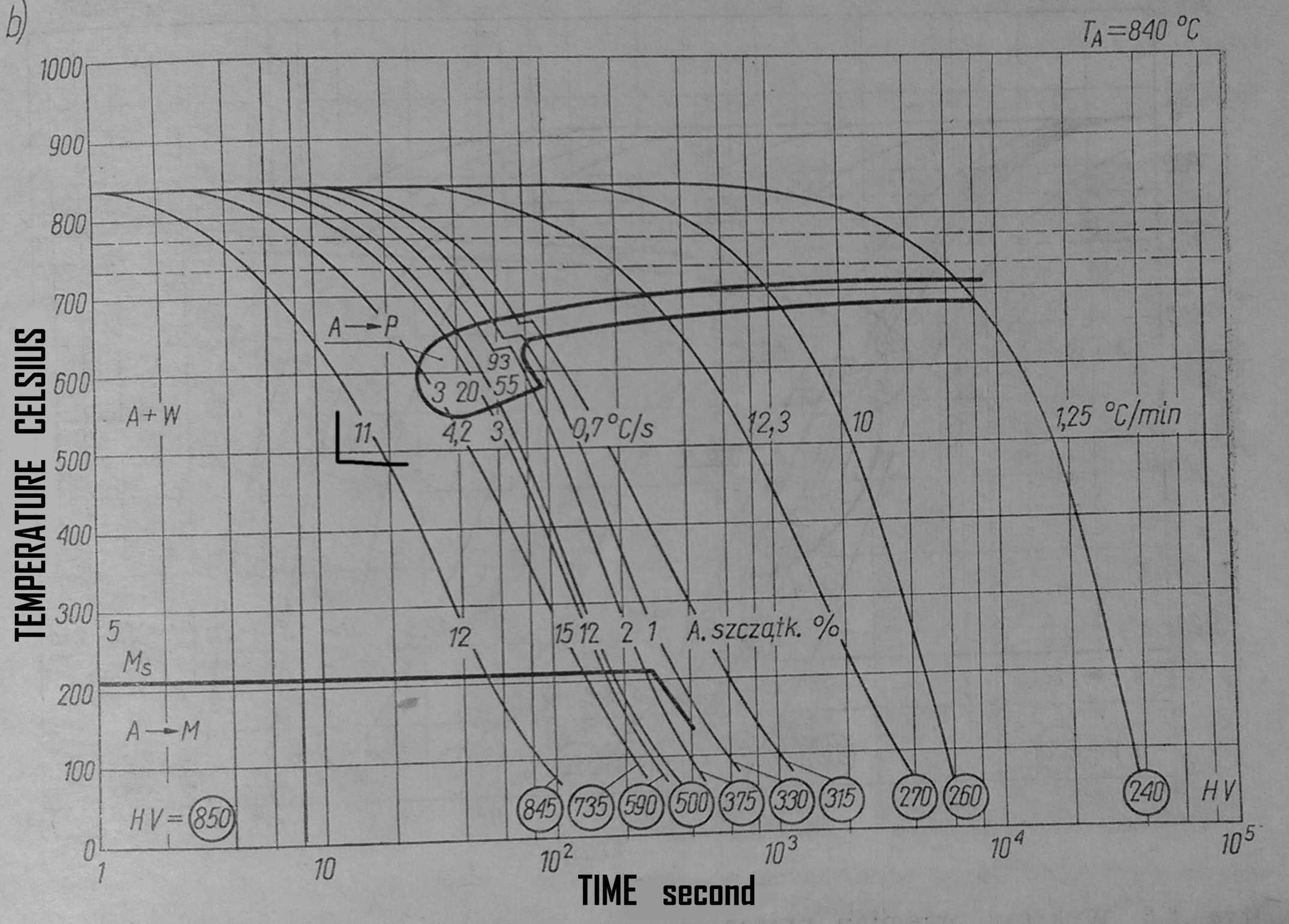

How to choose a cooling medium? Again: expertise and experience or trial and error method. Based on the CTT (Continuous Cooling Transformation) diagram for a specific steel! https://en.wikipedia.org/wiki/Continuous_cooling_transformation

Fig. 1 CCT diagram for LH15 (52100 AISI) steel, hardened at 860O C.

From this chart it is possible to calculate how quickly the medium needs to cool, in which the knife with thickness of 5mm e.g. will be extinguished. Luckily, for the author of this text, the cooling speeds and corresponding hardness after hardening are shown on the graph. For a cooling rate of 11O C/s, a hardness of 845 HV (65HRC) is obtained. This cooling rate will be ensured by hot hardening oil at a temperature of 70-200 OC.

Without access to such charts, the knifemaker can use publicly available information without any expertise: for that, steel (52100) it is recommended to be extinguished in oil. Even regular rapeseed oil from the shop can be used in this case.

Just a moment! Why use hot oil, it is unpleasant (oil stinks L), dangerous (oil burns heal for a very long time!). During extinguishing of knives in water or oil, very high thermal stresses (quick cooling) and structural stresses (martensitic transformation) are introduced. https://en.wikipedia.org/wiki/Diffusionless_transformation The stresses introduced sometimes cause the knives to curve, sometimes causing them to crack. Hot oil cools slower (it can be used here), the stresses are lower! There is one more bonus: when using hot oil >70 O C (preferably >120 O C), the detail has an oil temperature of at least higher after taking it out. In such a hot knife there was no real martensitic change and if it bent during the hardening process, it could be straightened with your fingers (with gloves, of course)! Later, the knife cools down in a relaxed manner on the open air, reaching the appropriate hardness, of course, it’s perfectly straight.

Knowing the type of steel used for the knife, you can find in the literature and on the Internet for the recommended cooling medium, but most often in general: water, oil, air, compressed gas. However, the information provided is incomplete: there are oil which cool as fast as water, water depending on temperature, cleanliness, additives (salt additive) can cool in a very wide range of speeds. Again: contact a specialist, be a specialist, or learn from your mistakes.

Hardening is done, but that's not everything: after hardening the knife is hard but fragile, sometimes just like glass!