After hardening, the workpiece is hard but brittle. Martensite, which appears in steel during hardening, has a very high stress in it, so that the knife is not brittle, it is necessary to remove some of this stress. https://en.wikipedia.org/wiki/Diffusionless_transformation The way to do this is to temper: reheat the steel to a certain temperature, heat it at this temperature and cool it to room temperature. Unfortunately, it is very underestimated. Why?

Another dilemma of a knifemaker: at what temperature should steel be tempered? Most often it is recommend to perform the tempering at the temperature chosen to match the required Hardness (HRC), and many people also assume that the Temperance (Toughness) increases with the decrease in hardness. That is the wrong approach.

The steels used in the production of knives are Hypereutectic alloy (Nadectoidal) alloys, i.e. steels with a carbon content of more than 0.8%. There can be less coal, Alloy Additives can cause, at lower Carbon content, steel can get Nadectoidal. Now it's enough to say that all tool steels used in the manufacturing of knives are exactly the same alloys, or they behave the same during tempering. In this type of steel the impact strength does not increase with decreasing hardness, the resistance to cracking depends on the tempering temperature!

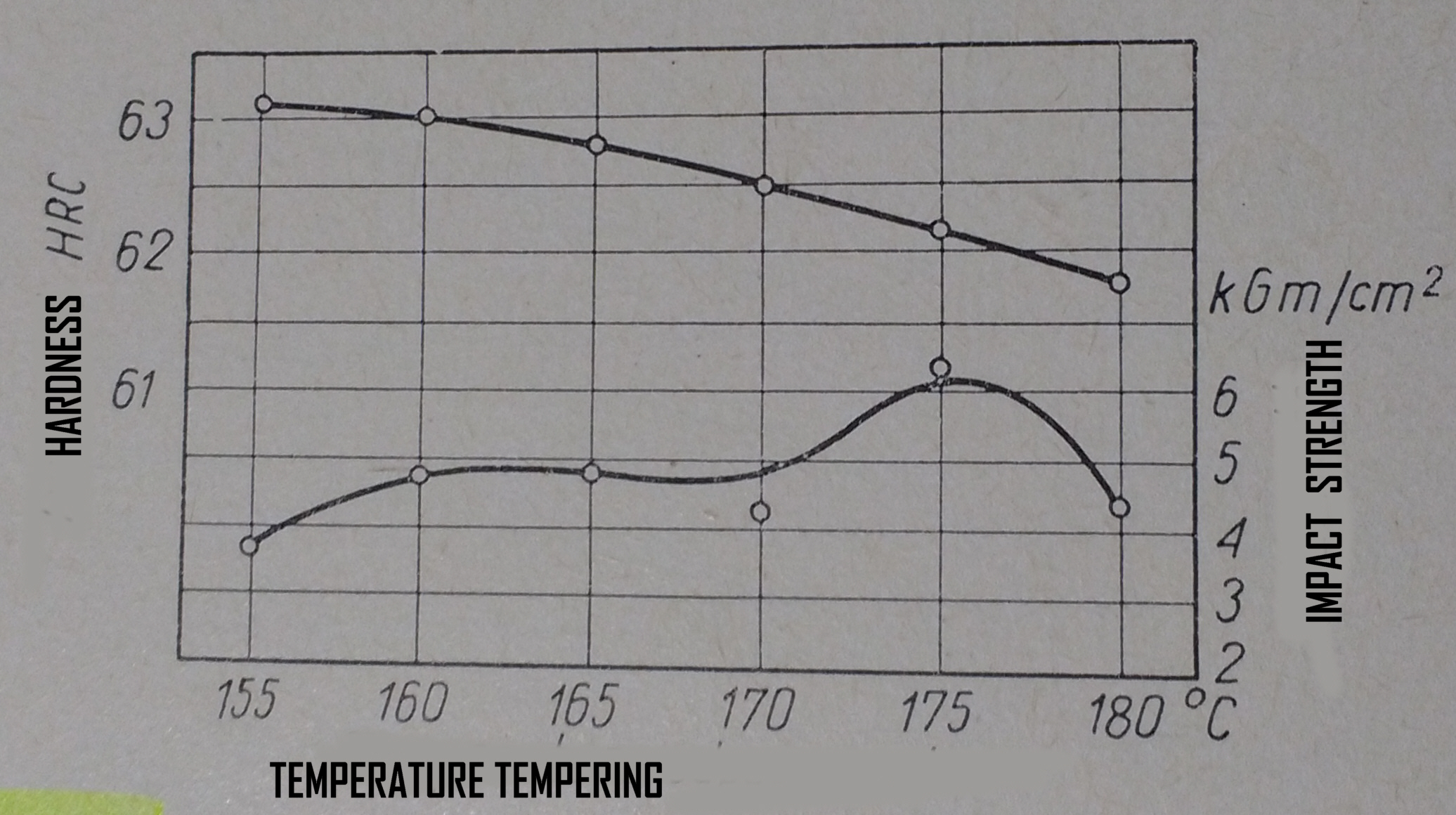

Fig. 1 Impact strength of LH15 (52100 AISI) steel depending on tempering temperature

As the graph shows, this steel has an impact peak at 175OC tempering point! And this is the only correct tempering temperature for low alloy Nadectoid steels with less than 3% Alloying Additives. Any other tempering temperature, even higher, does not guarantee a higher impact strength with a similar hardness. Similar impact strength as after tempering at 175OC is achieved only after exceeding 350 OC, but then their hardness can fall well below 48HRC.

The knives are also made with medium alloy steels (3-5% Alloyed additives content) and high alloy steels with more than 5% alloy content. Alloy additives affect many properties in steel, and also affect the appearance of the impact peak. Of course, it would not be very easy for a knifemaker to achieve this

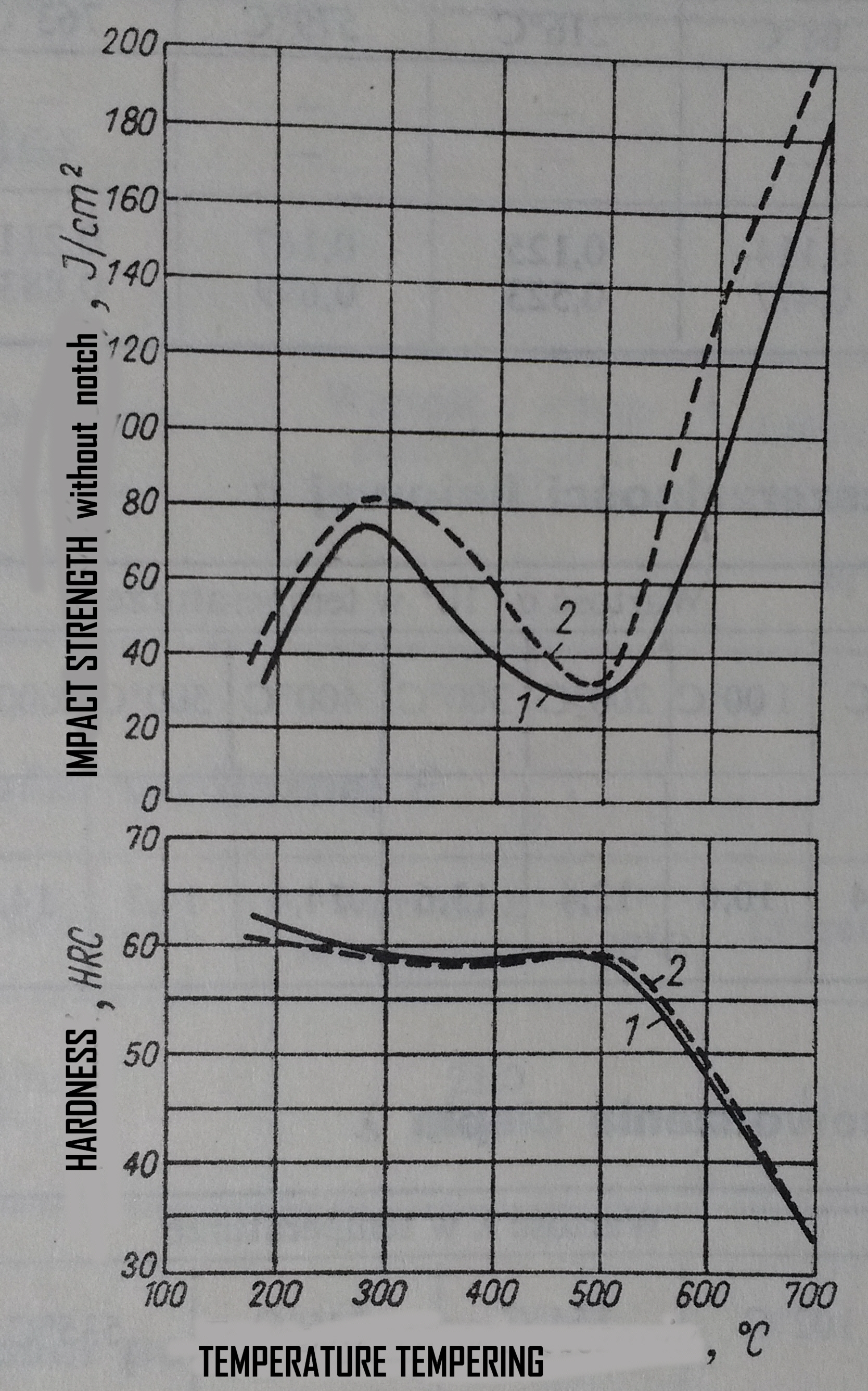

Fig. 2 Steel impact strength NC11LV (D2 AISI) depending on tempering temperature

As you can see with the NC11LV (D2 AISI) steel, the impact peak is shifted to a tempering point of approx. 280 OC! This is much more than 52100 AISI, and this is the correct tempering temperature for this particular steel. As you can see, a similar impact strength is obtained only after tempering at temperatures to approx. 580 OC, and then the hardness drops below 50HRC! How is it with other alloyed steels? All that remains is to look for specialist literature or to carry out many tests...

Luckily for the knifemaker, the tempering time is quite easy to determine. It takes about 1-2 hours, but 2 hours is a safer bet. At least this is not as difficult! J