Alloy components are added to the steel to change its properties, however, they are not used to deoxidize the steel, they are too expensive to do so.

Chromium (Cr) is the basic and most important alloy element in tool steels and structural steels used for making knives. It is so, because it is cheap J and does only good things. It forms hard Chromium Carbides (Cr3C2, Cr7C3, Cr23C6) which increase the wear resistance. It also affects grain growth in steel (just like Aluminium (Al)), but to a much lesser extent. Chromium Carbides inhibit grain growth at high temperatures. With their high content in steel (over 12%, depending on the carbon content), they make the steel rust resistant. It is thanks to Chromium that we have stainless steel!

Molybdenum (Mo) is the most underestimated alloy element in steel used in the manufacture of knives. It Increases crack resistance in hardened steels. In high alloy steels (content of alloy components above 5%), secondary hardness occurs during the tempering of steel, which is very often used by knife manufacturers. It also increases the hardenability of steel, with the strongest power among all elements. Of course, it increases the resistance of steel to grain growth (in high-alloyed steels), more than chromium. Molybdenum Carbides (MoC, Mo2C, Mo6C) are the reason. It also increases the wear resistance more than chrome.

Fig. 1 Effect of Molybdenum content on hardness during tempering of steel [1].

Wolfam (W) works in the same way as Molybdenum, but twice as weak. This is due only to its specific density, twice as high as in Molybden.

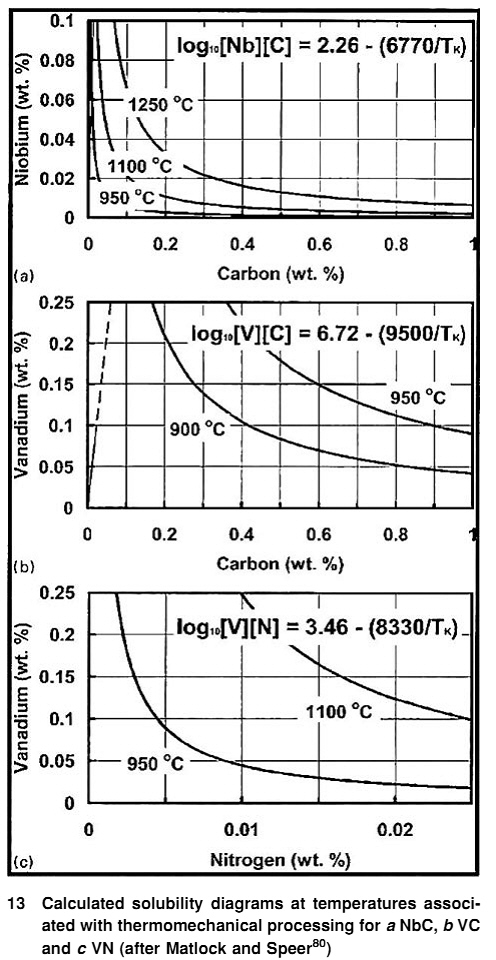

Vanad is a very important element in steel, it is added to almost every alloy tool steel. Even the lowest addition protects steel from grain growth (0. 1%) even more than Chromium, Molybdenum, Tungsten or Aluminium. Vanadium Carbide (VC) is the reason for this. In high alloy steels it is also responsible for the occurrence of Secondary Hardness, more strongly than the above mentioned elements.

Fig. 2 Solubility of vanadium carbides and nitrides in steel [2]

Nickel (Ni). Actually, it is not an alloy element in tool steels. However it often occurs in steel added to Damasts, steel with an increased content of Nickel after pickling Damasts is brighter, thanks to which etched Damast is simply nicer looking.

Bibliography

[1] https://www.imoa.info/molybdenum-uses/molybdenum-grade-alloy-steels-irons/tempering.php

[2] Thomas Neville Baker: „Microalloyed steels”, Iron making & Steel making. September 2015

Powered by MELONTOOLS