The material which is most commonly used in the manufacture of knives is steel. Below I present the first part of a brief description of steel.

Steel is an alloy of iron (Fe) with carbon (C) and other elements. Carbon is the main alloy element in steel.

Iron + Carbon. That could easily be enough, but such a pure alloy is very difficult to come by, and it also has some disadvantages: it will be prone to curvature and cracking during hardening, it is not resistant to grinding, it is very likely to get rusty. Above all, however, it would be expensive! That is why other elements are also present in steel: Chromium (Cr), Molybdenum (Mo), Tungsten (W), Vanadium (V), Manganese (Mn), Silicon (Si).

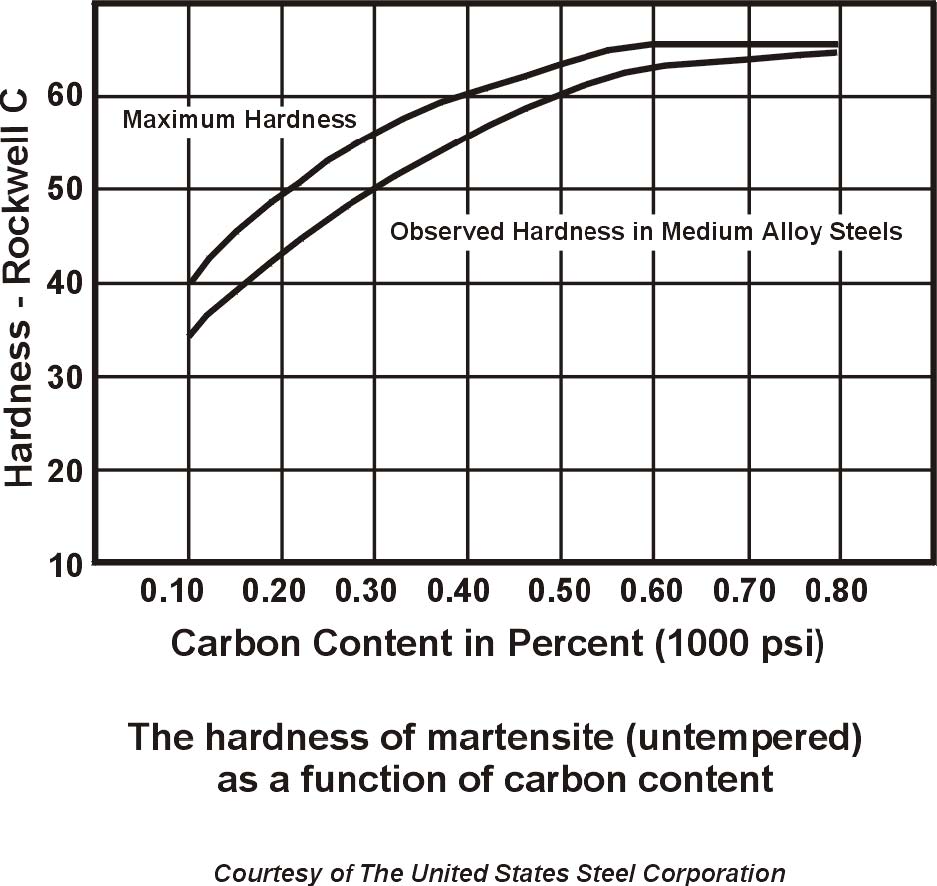

Special, hardened tool steels are most often used in the production of knives. They are cleaner (they have less harmful admixtures), more resistant to attrition than structural steels. It is thanks to the increased carbon content of 0. 4-3. 8% (compared to most structural steels) that tool steels achieve higher hardness after heat treatment (up to over 60 HRC) and are also more resistant to grinding. Please note that also structural steels can be used for tools. However, a knife made of tool steel will always be better than any other knife made of structural steel.

Fig. 1 Hardness of hardened steel in relevance to carbon content [1]

As one could observe after hardening of steel with a carbon content of 0. 4% you can get hardness after. 50HRC. So why add more carbon to your steel?

With the increase of carbon content:

- more carbides can be formed (of iron and alloyed elements), the more carbides are present, the more resistant the steel is to overheating (during hardening); for today only one fact is sufficient: less disposal to grain growth, more resistant to hardener errors,

- The higher attrition resistance,

- steel has a higher hardenability, for today it is enough to know that milder coolants can be used, which results in less susceptibility to cracking and cracking of steel during hardening.

Bibliography:

[1] https://www.engineersedge.com/

Powered by MELONTOOLS